Phil Dart

August 2020

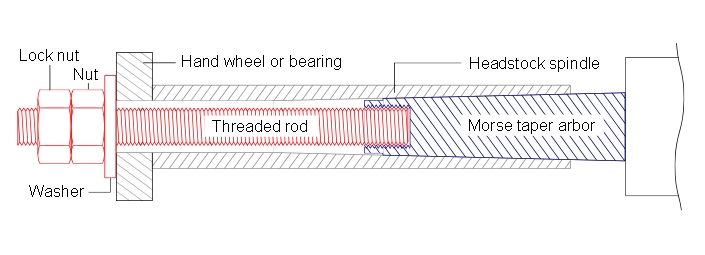

Morse taper attachments mounted in a lathe headstock are prone to work themselves loose whilst under power if unsupported by the tailstock. A draw bar is a method of keeping the attachment seated by clamping it in place. The draw bar screws into a female thread that’s often present on the small end of the tapered arbor of the attachment, and presses on the revolving hand wheel or bearing that’s at the opposite end of the headstock spindle to the lathe bed. Since every lathe is different, a draw bar isn’t something you can generally buy, but they are simplicity itself to make.

Firstly, identify the size of the thread which is inside the back end of the arbor of your morse taper attachment. 1MT arbors often have M6 threads and 2MT arbors often have M10 threads, but you can check with either a thread gauge or by screwing in an appropriate bolt to see if it will fit. You’ll need a metal rod which is long enough to screw inside that thread, and reach all the way through the spindle in your lathe headstock, so that it protrudes far enough out the other end in order to fit a washer and two nuts. You can either thread a steel rod yourself with an appropriate die or you can buy a rod from a hardware store which is already threaded along it’s entire length.

Offer up the MT attachment to your headstock spindle and roughly calculate the distance between the small end of the arbor and the outside edge of the hand wheel or bearing that’s at the other end of the spindle. Add about another 10cm to that to be on the safe side, and cut the rod to length.

If the rod is not already threaded at the arbor end, thread it now, securely fit the MT attachment to your lathe and screw the rod into the arbor through the hand wheel/bearing end of the spindle.

Obtain or make a washer with an inside diameter to suit the diameter of your rod, and an outside diameter large enough to more than cover the hole through the middle of your lathe hand wheel/bearing. It needs to be substantial enough and large enough to not bend or get pulled through. Place the washer over the rod and calculate how much you can trim the rod so that there’s enough left on it to fit a nut and a lock nut. Unscrew and remove the rod, then cut it to length accordingly.

Thread the rod at the nut end if not already done. Refit it to the lathe and screw it back into the arbor. Replace the washer, screw on a nut to a firm finger tightness, then fit a lock nut.

You have a draw bar.

To use, leave the nut and lock nut fixed in place - the draw bar is fitted and removed by screwing it in and out as a whole, not by removing the nuts. Don’t over-tighten it - a firm finger tightness is good enough. And don’t be tempted to use it as a knockout bar, which would be likely to damage either its own or the attachment's threads. If you need to knock out an arbor, use a proper knockout bar.

Your name *